Industrial Flooring

Home /

We are the best Waterproofing experts

We have listed 8000+ verified waterproofing contractors across 1000+ cities.Choose verified waterproofing contractors in Bangalore at MV Constructions.

For a lighthearted approach, try: “Go With the Float – Waterproof in Style.”

Industrial Flooring

Industrial flooring plays a critical role in ensuring the safety of commercial businesses. It provides a durable, hard-wearing surface ideal for withstanding heavy foot traffic and protecting workers and customers from accidents.

Epoxy Flooring

Epoxy floor coatings are commonly used for commercial and industrial flooring. Epoxy coatings are normally applied over concrete floors to provide a high-performance, smooth, and durable surface that can last many years and withstand heavy loads. Many industrial sites, warehouses, and commercial buildings rely on epoxy floors to maintain clean and safe conditions for workers, equipment, and inventory.

An epoxy coating requires a clean and slightly porous surface to adhere properly. Epoxy may not bond to sealed or polished concrete. The concrete also must be fully cured. Before apply epoxy floor coating, it is important to patch and repair all major cracks and chips in the concrete surface and to remove all grease.

Polyurethane Flooring

Polyurethane Floors are an alternative to epoxy flooring. They can be either one-component (moisture curing) or two component when they cure as a result of mixing two components together.Compared to Epoxy Floors, they tend to be softer and have a higher elasticity.

The most common forms of polyurethane flooring are:

- Roller and squeegee applied Floor Coatings

- Clear coats used to protect surfaces from scratching

- Varnishes for wooden floors

- Thicker floors applied with a trowel at a thickness of 2-3 mm

- Cement based polyurethane floor often applied at thicknesses up to 1cm

EPU Flooring

Antistatic Flooring

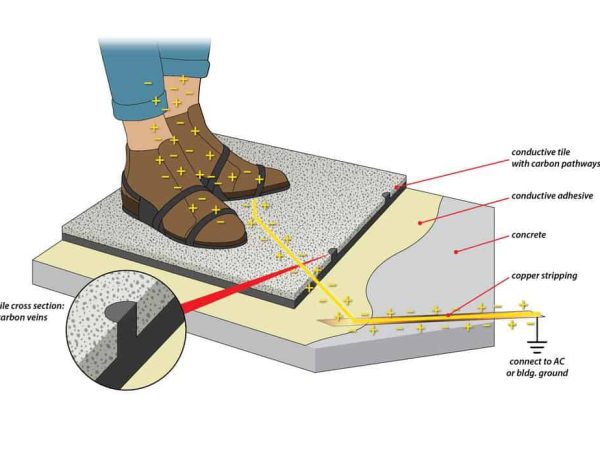

Anti-static industrial floors inhibit the generation of electrostatic discharge or ESD, which is the pulse of static electricity that happens when a charged person or surface comes into contact with another object.

Selecting the right industrial flooring for your needs can be a complicated undertaking. Besides the obvious considerations of colour and material, there may be specific performance requirements to take into account, particularly when the area may be used for highly sensitive operations such as healthcare or delicate manufacturing processes.For a wide range of industries, one critical consideration is whether a floor needs to be anti-static. Determining that answer is just the first step: if you need anti-static flooring, you also need to know the types available, the benefits and the options to consider when choosing an anti-static floor provider.

ESD Flooring

Electrostatic Discharge (ESD) flooring protects electronics from damage caused by static electricity, which accumulates as people walk. Conductive elements such as carbon, graphite or metal-coated particles, distributed throughout the flooring material, give ESD floors electrical conductivity, and create an electrical pathway from the walking surface to ground.

ESD flooring standards are based on an ESD flooring/footwear combination. Some, but not all, ESD floors also prevent charge generation – i.e., static from accumulating as people walk. Thus, it’s critical to determine the type of footwear people will use in the space. When choosing an ESD floor, always test for both electrical resistance (STM7.1) and charge generation (STM97.2-2014).

Car Parking Epoxy System

Epoxy /PU flooring solution provides aesthetically good seamless anti-skid flooring at the car park area with the proper marking of driveways, pathways, entry-exit arrows, direction arrows along with floor layout, fluorescent reflectors, etc. It helps for smooth and safe operation, atmospheres in the respective areas.

As every concrete surface is subject to unique operating and environmental conditions we specify accurate flooring systems.

We offer the Best Epoxy / PU flooring Solutions for car park epoxy flooring with quality satisfaction and good price.